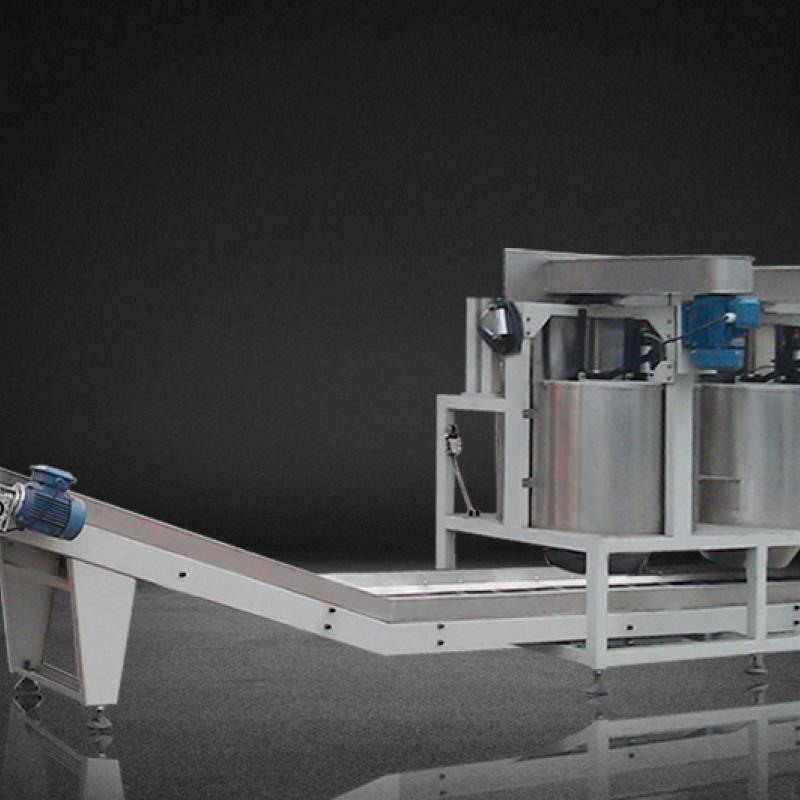

The bread crumb production line developed by our company adopts a twin-screw extrusion puffing process, which converts flour or other powdered grain raw materials into crumbs, needle shaped or flake shaped bread crumbs and snowflake flakes. The production process includes feeding, mixing, puffing, cooling, crushing, etc. Compared to traditional baking methods for producing bread bran, the use of puffing technology has advantages such as high yield, high continuous production capacity, energy conservation, and labor saving.

Contacta ahora

Snow flake and bread bran production lineThe snowflake and bread bran production line is exclusively developed and produced by Dayi, which is the first in China and another innovative application of twin-screw extrusion technology. The production process has been fully automated.

Contacta ahora

This process line adopts advanced share extrusion technology, which can extrude products with different textures and tastes out of double- screw extruder at the same time. It can produce a variety of core-filling food which are popular in the market, such as fragrant chicken, core- filling rolls, etc. It can also produce nutritional powder, grain gruel and many other snacks by changing moulds and assistant equipments.

Contacta ahora

Equipment introductionThis complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, conveying, oil filtering and seasoning, and the control is accurate and reliable. The equipment is frying while conveying, with strong continuous production without interruption, which greatly improves production efficiency and saves a lot of human resources. Frying oil turnover rate is high. The pot body and the conveying can be separated freely, which is

Contacta ahora

Equipment introductionThis complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, conveying, oil filtering and seasoning, and the control is accurate and reliable. The equipment is frying while conveying, with strong continuous production without interruption, which greatly improves production efficiency and saves a lot of human resources. Frying oil turnover rate is high.

Contacta ahora

Overview:The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying.

Contacta ahora

This technique line is one of the newly advanced double-screw extruding techniques of our company. the traditional stir-fry handiwork has low efficient and less usable uncooked substances, and its sanitation and best are hard to govern. the double-screw extruding approach makes up the ones lacknesses. it not best can manner grain materials, like buckwheat, oats, and many others.

Contacta ahora

Triangle and doritos chip production line is mainly made of corn flour and rice flour as main raw materials, which are extruded, calendered into thin slices of various shapes, and then baked and flavored. It has become a best-selling food for all ages at home and abroad because of its advantages of crispy, delicious, long-term eating and easy digestion. Triangle and doritos chip production line integrates extrusion, molding and other production processes, with a high degree of automation.

Contacta ahora

This process line adopts superior share extrusion generation, that can extrude merchandise with unique textures and tastes out of double- screw extruder at the equal time. it is able to produce a diffusion of center-filling food which can be popular within the marketplace, including fragrant fowl, core- filling rolls, and so forth. it could additionally produce dietary powder, grain gruel and many different snacks by way of changing moulds and assistant equipments.

Contacta ahora

Introduction of nutritional rice and instant rice production lineNutritional rice and instant rice production line is a food production equipment developed by Dayi according to the development trend of food in my country.There are two production processes of nutritional type and brewing type. The overall operation is stable, the degree of automation is high, and the operation is simple.

Contacta ahora

This puff snack making system can use corn, rice, and other grain powder as uncooked materials to deliver proper away puffed snacks in variou shapes, together with chip, ball, ring, stick, flake, flower, and plenty of others. after dried and flavroed, the snacks are crispy and attractive which is probably very famous within the marketplace.

Contacta ahora

OverviewThis complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, oil rejection, and lifting. A series of actions are controlled by PLC centralized automatic control, which makes the control accurate and reliable, greatly improves the production efficiency, and saves a lot of human resources.

Contacta ahora

This technique line is newly designed and produced with foreign places superior technology. it has progressed the risks of import device which consist of large funding and excessive production charge. this line makes use of corn starch, wheat flour, potato starch as substances to supply"bugles", "internet", "potato chips" and hundreds of numerous 3-d compound extrusion meals. this line can be in contrast with those import equipments. underneath the equal features, its price is satisfactory one tenth of that of import machine.

Contacta ahora

This system line is newly designed and produced with foreign superior generation. it has advanced the dangers of import device together with large funding and high manufacturing price. this line uses corn starch, wheat flour, potato starch as materials to produce"bugles", "web", "potato chips" and lots of other three-D compound extrusion food. this line can be compared with the ones import equipments. below the same features, its fee is most effective one tenth of that of import equipment.

Contacta ahora

This technique line is newly designed and produced with overseas superior generation. it has stepped forward the dangers of import system consisting of huge funding and excessive production value. this line makes use of corn starch, wheat flour, potato starch as substances to supply"bugles", "net", "potato chips" and plenty of different 3-D compound extrusion food. this line can be in comparison with the ones import equipments. beneath the same features, its fee is only one 10th of that of import equipment.

Contacta ahora

This process line is newly designed and produced with foreign advanced technology. It has improved the disadvantages of import equipment such as large investment and high production cost. This line uses corn starch, wheat flour, potato starch as materials to produce"bugles", "web", "potato chips" and many other 3D compound extrusion food. This line can be compared with those import equipments. Under the same functions, its price is only one tenth of that of import equipment.

Contacta ahora

Bugles making machine makes use of corn powder, corn starch, and rice powder as most important material that are extruded, punched into triangle, round, square shapes, after which baked and flavored. such snacks with crispy flavor, rich nutrition and digestible structure are very popular with many people all over the global.

Contacta ahora

The TSP fiber soy protein is made of low temperature defatted soy flour, wheat protein, soybean and isolated protein as the main raw materials, and produced through mixing, cooking, and extruding in the double-screw extruder under high temperature and high pressure. The fiber soy protein is in strong muscle fiber structure with high tenacity which can keep good water and oil absorption ability, so it can be widely used in meat, fast food, instant food, fillings as vegetarian meat.

Contacta ahora

Meat analog make system is designed and produced with our rich evaluations on food extruder enterprise for over 20 years. it adopts nonfat low temperature soya bean meal as most vital raw material to supply all varieties of textured protein food, that is nutritional and resultseasily absorbed with the resource of human frame. such soya protein meals looks like real muscle meat and mastication. textured soya protein meals is extensively appied to many industries, together with can food, sesoning meals, ham, cooking, and so forth.

Contacta ahora

Soy protein mock meat processing line is designed and produced with our wealthy experiences on meals extruder enterprise for over 20 years. it adopts nonfat low temperature soya bean meal as major uncooked material to supply all types of textured protein food, which is dietary and effortlessly absorbed with the aid of human frame. such soya protein food seems like actual muscle meat and mastication. textured soya protein food is widely appied to many industries, inclusive of can meals, sesoning food, ham, cooking, and so on.

Contacta ahora

Soy protein mock meat processing line is designed and produced with our rich reviews on meals extruder enterprise for over two decades. it adopts nonfat low temperature soya bean meal as major uncooked cloth to deliver all varieties of textured protein food, that's dietary and effects absorbed with the aid of human frame. such soya protein meals seems like actual muscle meat and mastication. textured soya protein meals is widely appied to many industries, together with can food, sesoning meals, ham, cooking, and so forth.

Contacta ahora

Vegetarian soye meat making machine is made of low temperature defatted soy flour, wheat protein, soybean and remoted protein as the primary uncooked materials, and produced thru mixing, cooking, and extruding inside the double-screw extruder underneath high temperature and high pressure. the fiber soy protein is in strong muscle fiber structure with excessive tenacity that may maintain suitable water and oil absorption capacity, so it may be extensively used in meat, speedy meals, instant meals, fillings as vegetarian meat.

Contacta ahora

The products produced by the soy protein production line are mainly made from low-temperature soybean meal, soy protein isolate, gluten powder, and other raw materials. The process of mixing and homogenizing materials, steaming and ripening, high-temperature sterilization, and extrusion molding is completed in a twin-screw extruder to produce high-strength and high toughness soy protein food with a layered muscle fiber structure, similar to the taste and texture of meat.

Contacta ahora

Equipment introductionThis machine is a special equipment for drying semi-puffed food. It can dry food blanks of various shapes such as potato chips, French fries, spirals, shells and crisp corners. It has a wide range of applications.This machine uses the combustion chamber for heating, and uses the chain to drag the stainless steel mesh belt for transmission. And it is equipped with an advanced frequency conversion speed regulation system, which can set different transmission speeds according to different materials.

Contacta ahora